304 Stainless Steel Plate

After sales service: online service

Sample: free sample

Customization: Support customization

Minimum order quantity: no minimum order quantity

Manufacturer:factory,manufacturers,OEM,ODM,company

Classification :

Keywords :

Stainless Steel Plate

PRODUCT DETAILS

| Stainless Steel Plate | |

| Product Name | Stainless Steel Plate, Stainless Stainless Sheet |

| Standard | GB, AISI, ASTM,DIN, EN, JIS |

| Available Grades | 200 Series: 201, 202 |

| 300 Series: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H | |

| 400 Series: 409, 410S, 416, 420, 430, 439, 440, 444, 446 | |

| Duplex and Others: 2205, 2507, S31803, S32205, S32750, S32760, 253MA, 254SMO, 904L etc | |

| Process | Hot Rolled, Cold Rolled, Forged |

| Sizes | Thickness: 0.3-200mm, Width: 10-4000mm (according to customer's request) |

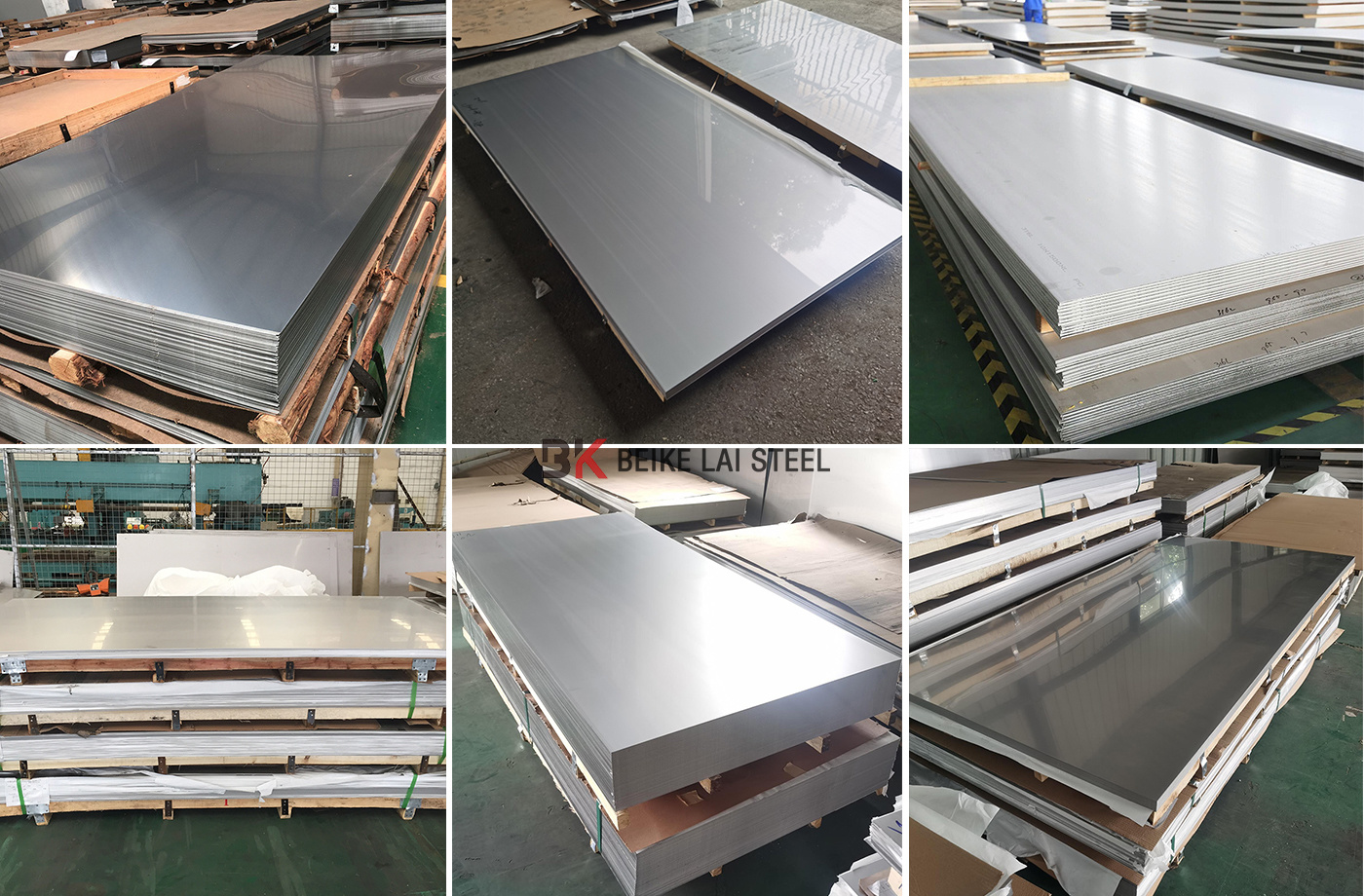

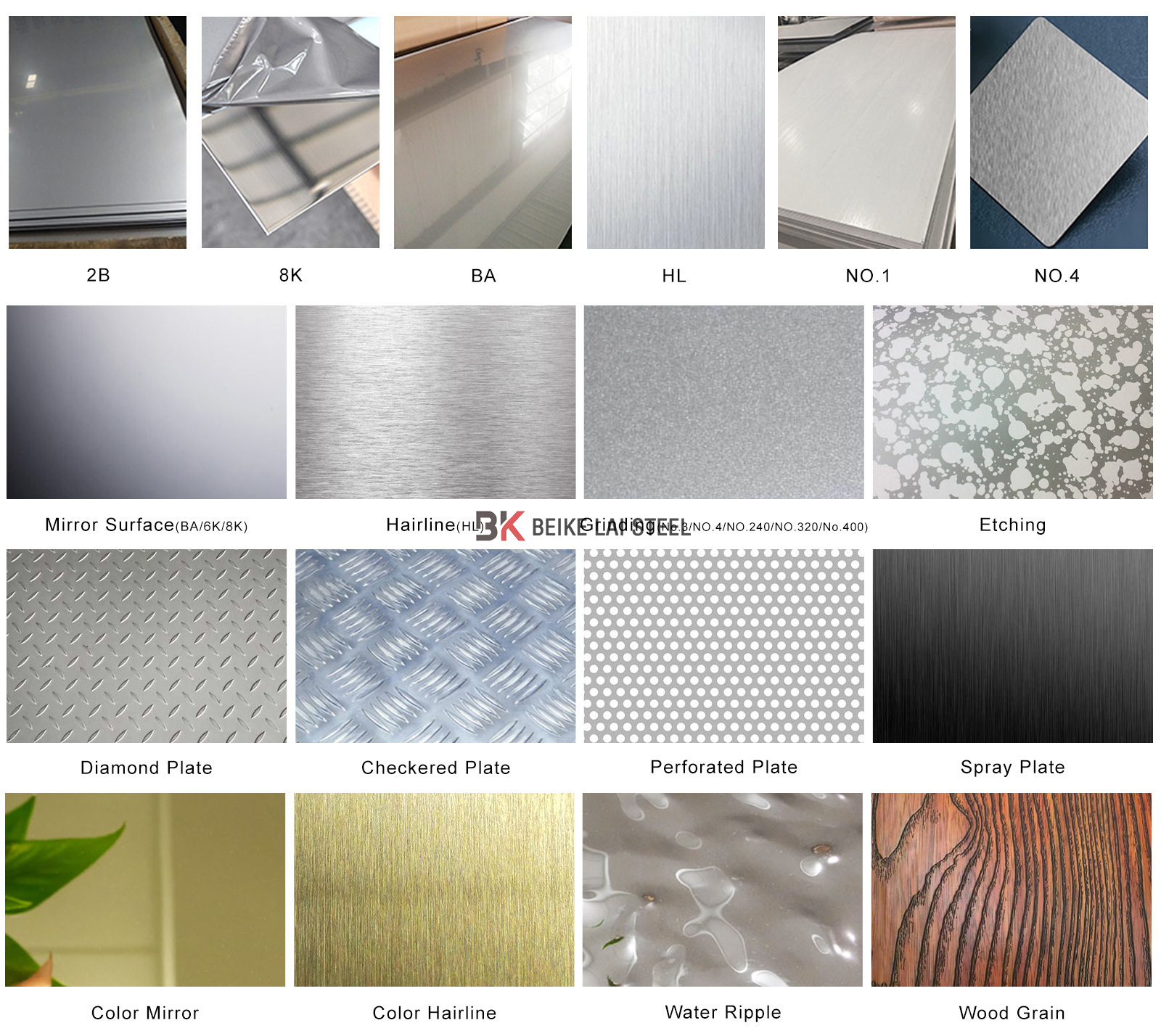

| Surface Treatment | NO.1, 1D, 2D, 2B, NO.4, BA, HL, Mirror, Embossim, Sandblasted |

| Fabricating | Rolling, Bending, Sllitting, Decoiling, Cutting, Drilling, Punching, Beveling, Welding etc. |

| Application | Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

| Finish | Description | Thickness (mm) | Width (mm) |

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.70 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.90 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.20 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.50 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.60 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2.00 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.50 | 914, 1219 & 1500 |

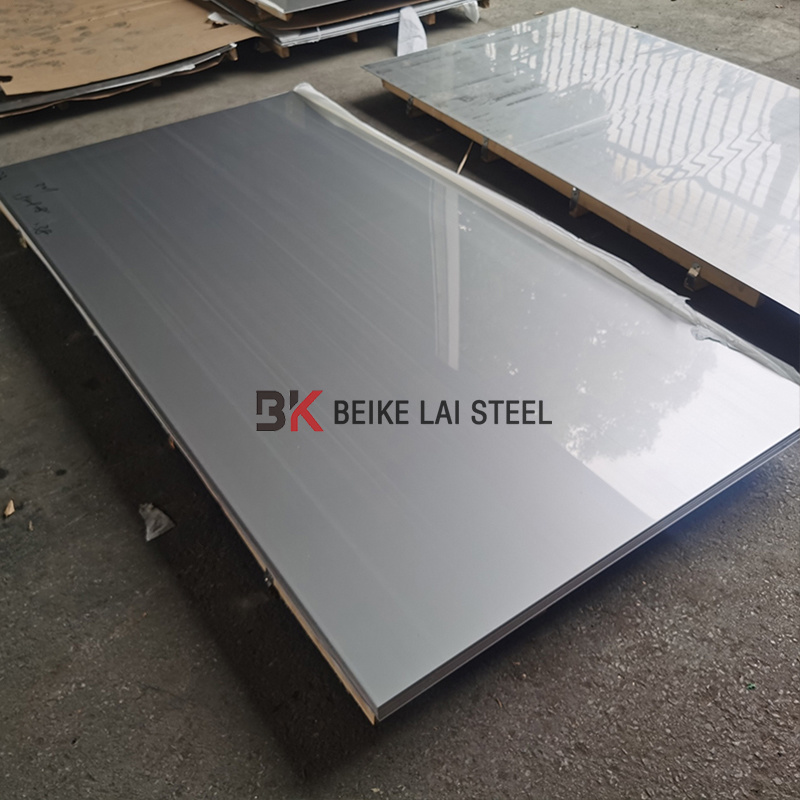

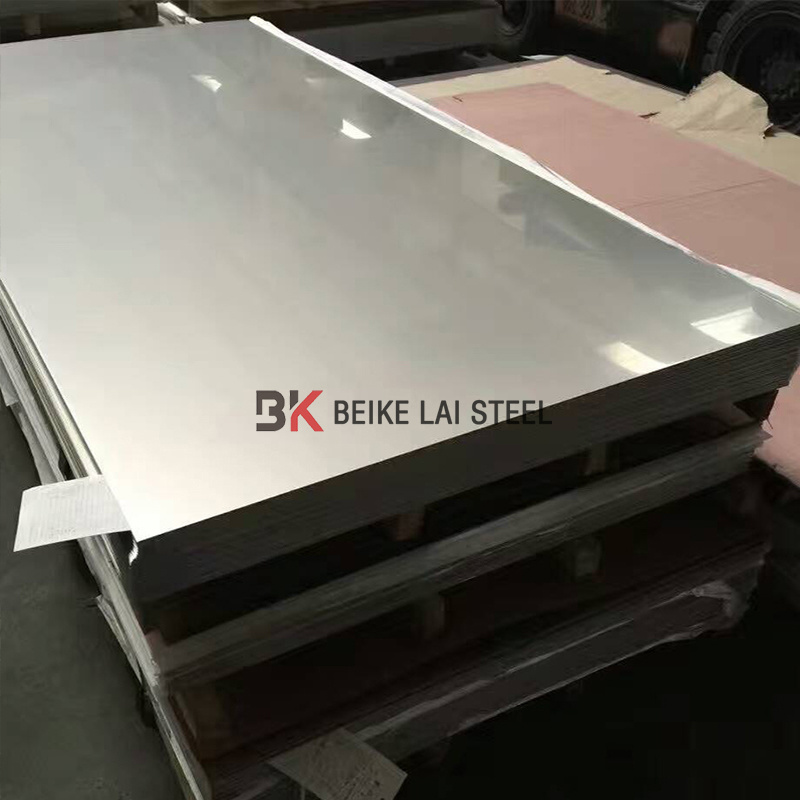

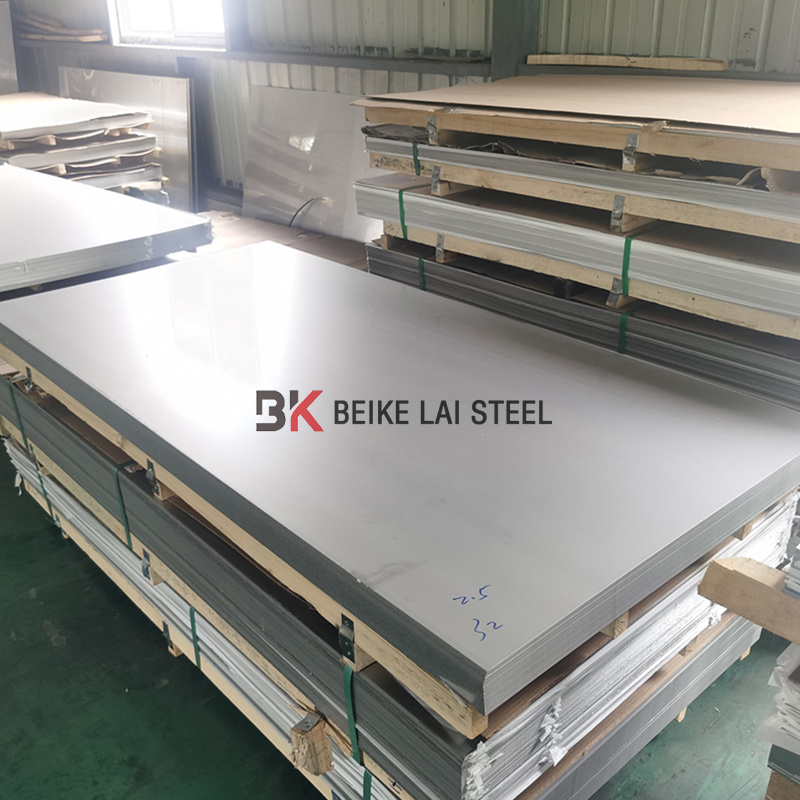

The Cold rolled 304 stainless steel sheet for industrial use is a high-performance material designed for demanding industrial applications. Known for its superior corrosion resistance, durability, and smooth finish, this 304 stainless steel sheet is ideal for manufacturing, construction, and machinery components. The cold rolled process enhances its strength and dimensional accuracy, ensuring reliable performance in harsh environments.

With excellent formability and weldability, the Cold rolled 304 stainless steel sheet for industrial useis versatile for fabrication into various shapes and structures. Its low carbon content prevents carbide precipitation, making it suitable for welding without compromising integrity. Whether used in chemical processing, food production, or architectural projects, the cold rolled 304 stainless steel sheet delivers unmatched quality and longevity.

Engineered to meet industry standards, this stainless steel sheet offers a polished surface finish, reducing the need for additional treatments. Choose our Cold rolled 304 stainless steel sheet for industrial use for a dependable, high-strength solution that meets the toughest industrial requirements.

Surface Selection

Plant appearance

The steel plant has world-class production equipment, including large blast furnace, modern converter, efficient continuous casting machine and precision rolling production line, to ensure high quality and stability of products

Packing And Delivery

Beike Laigang Steel products are widely used in various fields and have been service more than 8 years. Customers are full of African, Europe, American and etc.

Customer visits

Beike Laigang Steel is specialized in various kinds of stainless steel pipe, plate, coil, bar, pipe fitting, high nicked alloy steel products, high temperature resistant products, and other OEM&ODM service.

Application

Stainless steel plates are widely used in many fields due to their high strength, corrosion resistance, and easy cleaning. The following is a detailed classification of their main uses: 1. Chemical and petrochemical 2. Construction and decoration 3. Machinery manufacturing and aerospace 4. Food processing and pharmaceutical manufacturing 5. Energy and environmental protection 6. Modern art and fashion design.

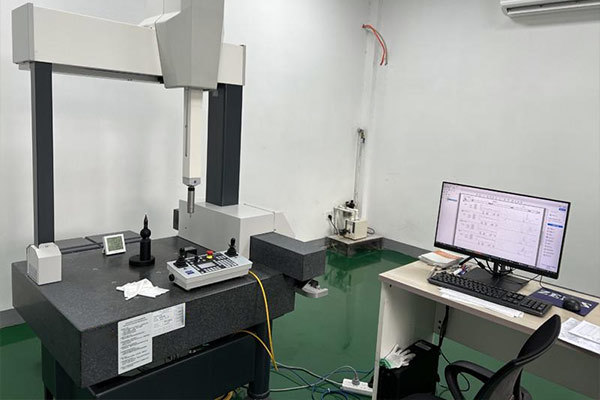

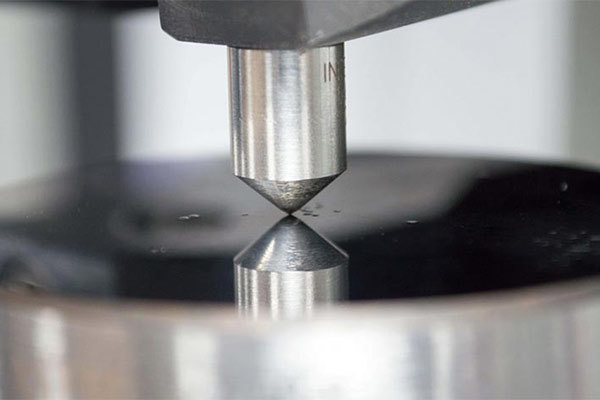

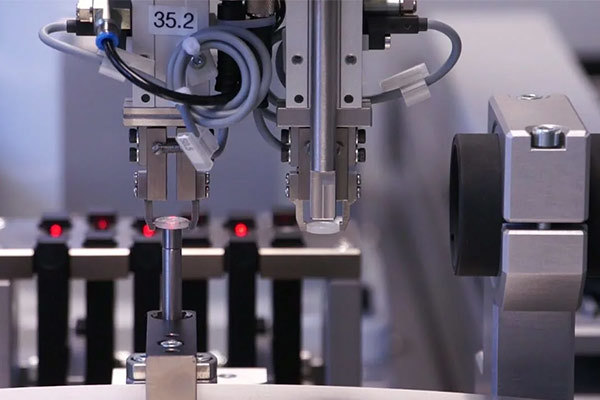

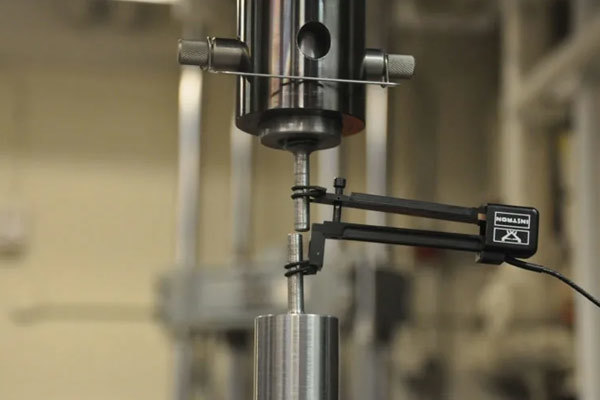

Product Inspection

Tensile strength test

Physical performance detection

Hardness detection

Mechanical performance testing

Testing equipment

Chemical composition detection

Spectroscopic detection

Tensile testing of steel

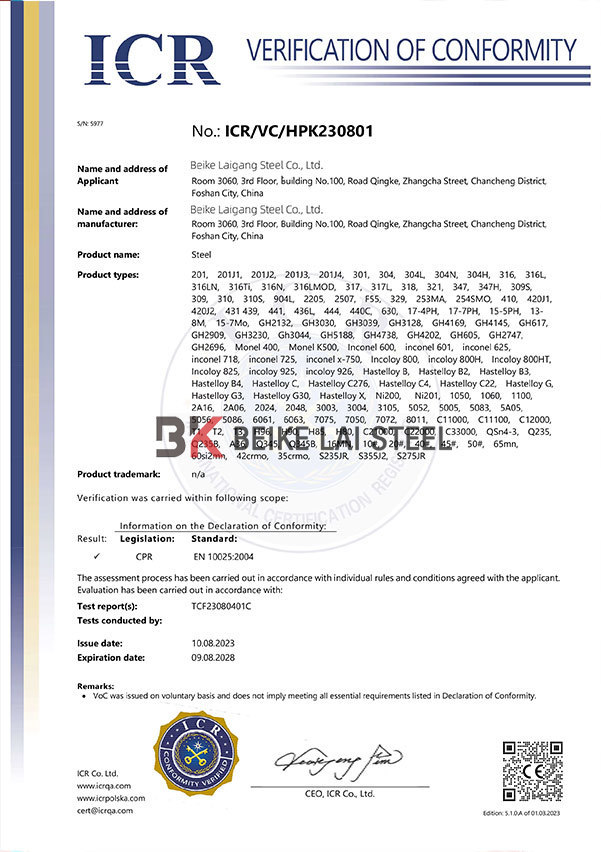

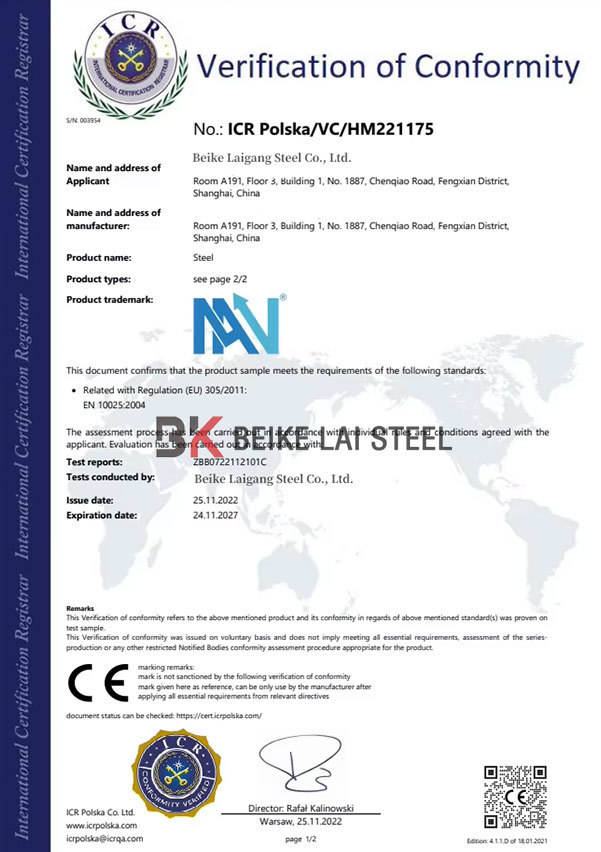

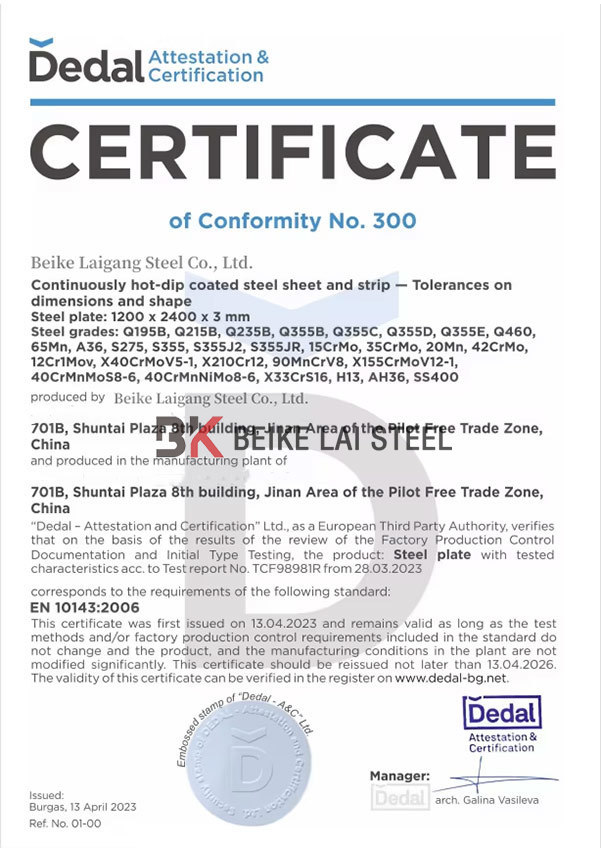

Certificate

CUSTOMER VISIT

COOPERATIVE PARTNER

APPLICATION

FAQ

RELATED PRODUCTS

GET A FREE QUOTE