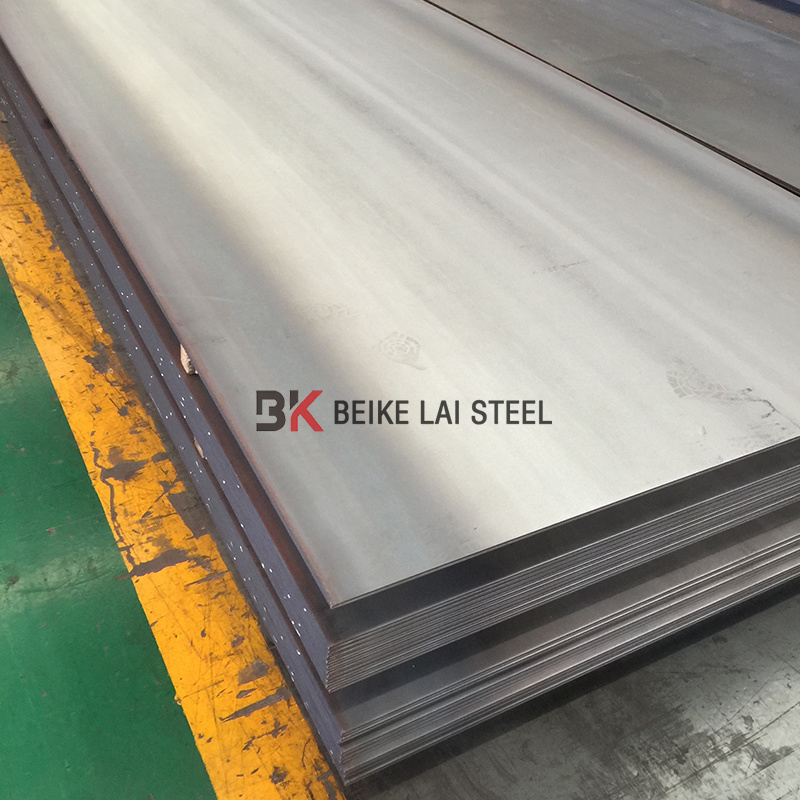

A515 Carbon Steel Plate

After sales service: online service

Sample: free sample

Customization: Support customization

Minimum order quantity: no minimum order quantity

Manufacturer:factory,manufacturers,OEM,ODM,company

Classification :

Keywords :

Carbon Steel Plate

PRODUCT DETAILS

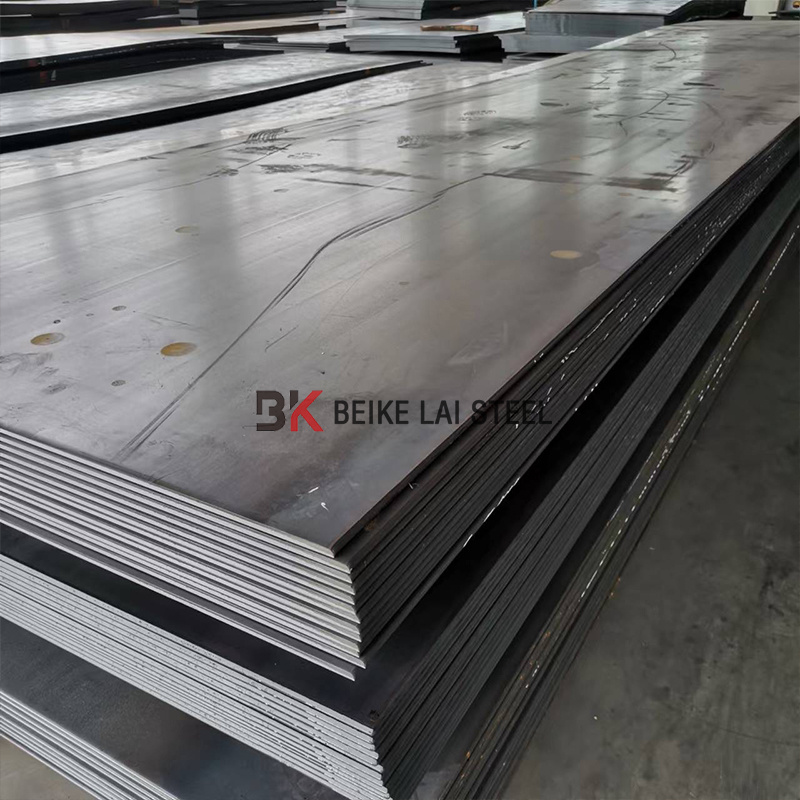

Thickness | 0.4-80mm | 0.015"-3.14" inch |

Width | 100-3500mm | 3.93"-137" inch |

Length | 1-18m | 39"-708" inch |

Surface | Oiled, Black Painted, Shot Blasted, Hot Dipped Galvanized, Checkered, etc. | |

Process | Cutting, Bending, Polishing, etc. | |

Application | Pressure vessel plate, Boiler plate for high temperature service, etc. | |

*Here are normal size and standard, special requirements please contact us | ||

Low Carbon Steel Plate is a fundamental and versatile material in countless industrial and construction applications. Its popularity stems from an excellent balance of strength, formability, and cost-effectiveness. This specific category of steel contains a low percentage of carbon, which is the key to its superior weldability and ductility compared to higher carbon alternatives. Whether you are fabricating structural frames, automotive components, or machinery parts, this material provides a reliable foundation.

The manufacturing process of our Low Carbon Steel Plate is meticulously controlled to ensure consistent quality and performance. We employ advanced rolling and finishing techniques to achieve precise dimensional tolerances and a uniform surface quality. This rigorous production standard guarantees that every plate meets the demands of your most challenging projects. You can trust in the reliability of our steel for critical applications.

A significant advantage of using our Low Carbon Steel Plate is its exceptional ease of fabrication. It can be easily cut, drilled, punched, and formed into complex shapes without compromising its structural integrity. Furthermore, its excellent weldability allows for strong, clean joints using all common welding methods. This makes the Low Carbon Steel Plate an ideal choice for custom fabrication and large-scale assembly lines.

In summary, for projects demanding a dependable, easy-to-work-with, and economical material, our Low Carbon Steel Plate is the premier selection. Its combination of mechanical properties and fabrication flexibility streamlines production and ensures long-term performance. We invite you to experience the quality difference and make this essential Low Carbon Steel Plate the core of your next manufacturing success.

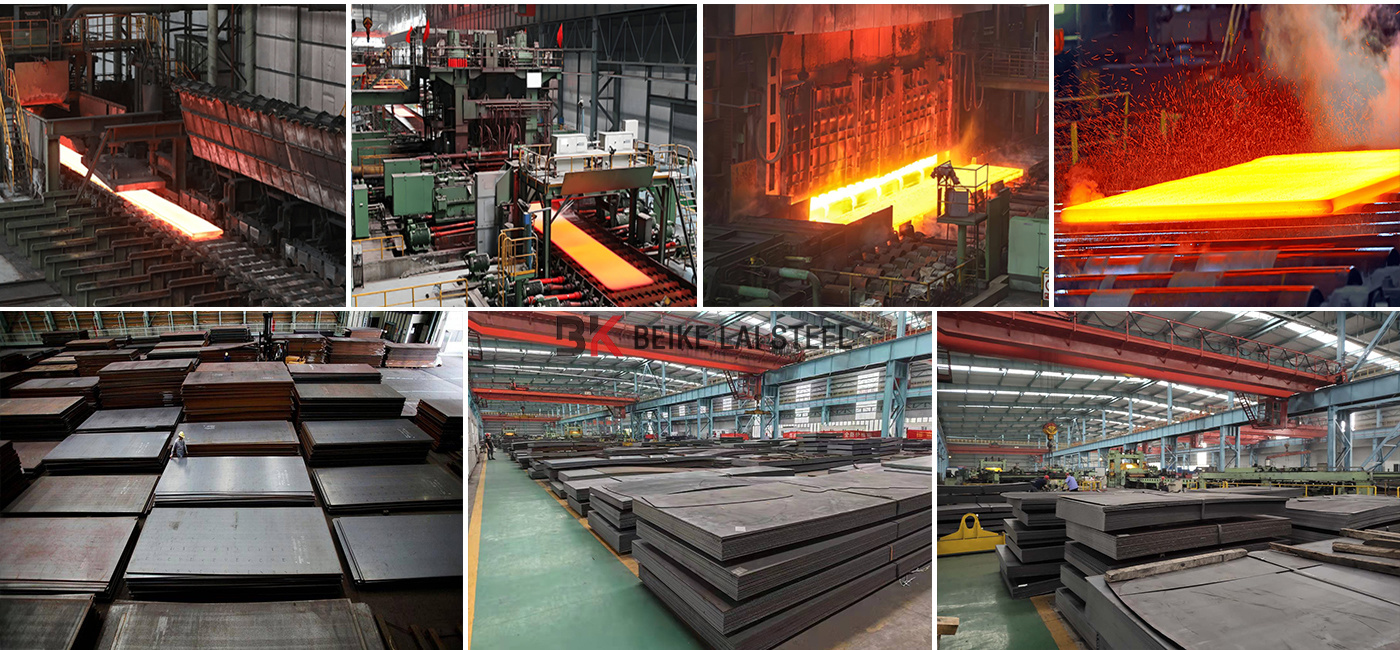

Plant appearance

The steel plant has world-class production equipment, including large blast furnace, modern converter, efficient continuous casting machine and precision rolling production line, to ensure high quality and stability of products

We have advanced processing equipments, the experienced team, strictly controls every detail of the product, equipment to strictly control the product quality. Strictly follow customer customization requirements for product production to meet customer customization requirements.

Packing And Delivery

Beike Laigang Steel products are widely used in various fields and have been service more than 8 years. Customers are full of African, Europe, American and etc.

Customer visits

Beike Laigang Steel is specialized in various kinds of stainless steel pipe, plate, coil, bar, pipe fitting, high nicked alloy steel products, high temperature resistant products, and other OEM&ODM service.

Application

Uses of Carbon Steel Plates

Carbon steel plates are widely used in many fields such as construction, machinery, and transportation, depending on their carbon content, processing technology, and performance differences. The following are the main classifications of their uses and typical application scenarios:

1. Construction and Infrastructure

Steel Structure Buildings: Such as house beams, roof panels, wall panels, and high-rise building towers, high-strength carbon steel plates such as A36 medium-thick steel plates are used to ensure the stability of the load-bearing structure.

Bridge Engineering: Used for main beams, cross beams, and connectors, which must have both high strength and corrosion resistance.

2. Mechanical Manufacturing

Low-carbon steel plates (carbon content <0.25%): Used for stamping parts (such as containers, instrument housings) and carburized parts (such as gears, pins), because of their good plasticity and strong weldability.

Medium-carbon steel plates (carbon content 0.25%-0.55%): After quenching and tempering, they are used to manufacture shafts, bolts, sleeves, etc., and surface quenching can improve wear resistance, suitable for high-load parts such as gears.

3. Transportation and Energy Vehicle Manufacturing: Medium and thick carbon steel plates are commonly used in chassis, carriages and other structural parts. Shipbuilding and Energy Equipment: Structural carbon steel plates with excellent toughness are required for hull structures and large motor housings. 4. Tools and Special Parts High Carbon Steel Plates (Carbon Content>0.6%): Used for springs (such as valve springs, leaf springs) and high-hardness tools after quenching. Ordinary Carbon Steel Plates: Such as Q195 steel, used in low-strength demand scenarios such as anchor bolts, rivets, and protective covers. Summary: The core difference in the use of carbon steel plates comes from the carbon content. From the toughness requirements of building structures to the high-strength requirements of mechanical tools, its classification (low carbon, medium carbon, high carbon) directly corresponds to different industrial scenarios.

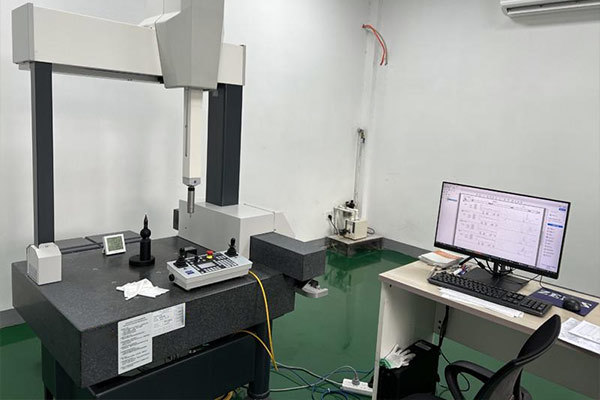

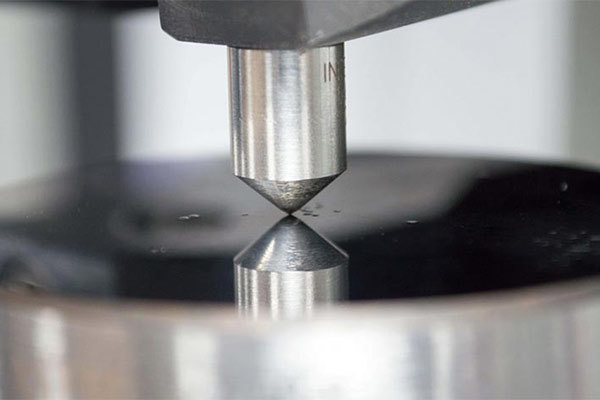

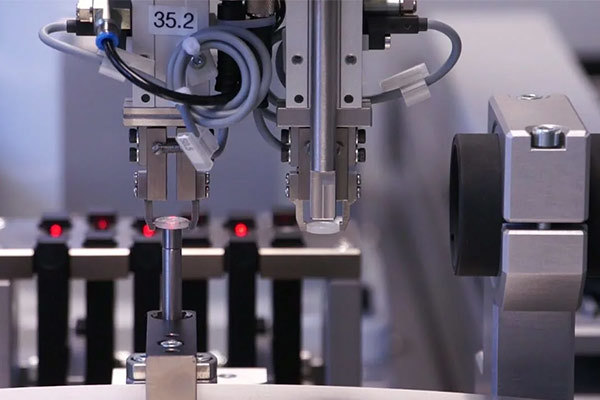

Product Inspection

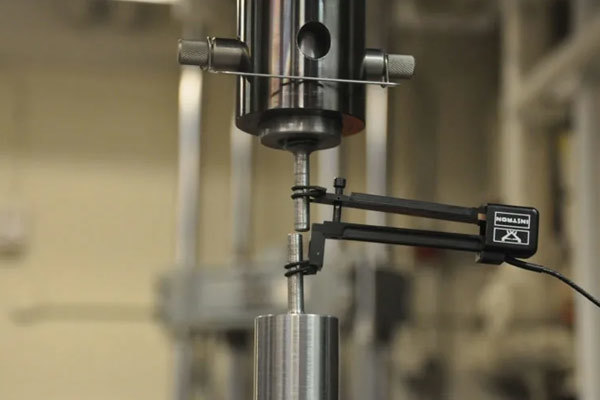

Tensile strength test

Physical performance detection

Hardness detection

Mechanical performance testing

Testing equipment

Chemical composition detection

Spectroscopic detection

Tensile testing of steel

Certificate

CUSTOMER VISIT

COOPERATIVE PARTNER

APPLICATION

FAQ

RELATED PRODUCTS

GET A FREE QUOTE